Ubuncinane boMyinge weodolo:Iikhilogram ezingama-500

Iinkcukacha zokuPakisha:1000kg / umgqomo

Ixesha lokuzisa:Kwiintsuku ezilishumi emva kokufumana intlawulo kwangaphambili

Ubunakho bokubonelela:Iitoni ezi-2 ngosuku

Umbala:Ulwelo olungenaMbala ukuya koMthubi

Ubunzima obuthile:1.00-1.10

PH:13.0-14.0

Ialkalinity yasimahla (piont):≥20

Ukupakisha:1000kg / umgqomo

Ixesha lokuqinisekisa:Unyaka omnye

Inkcazo

1. emfutshane

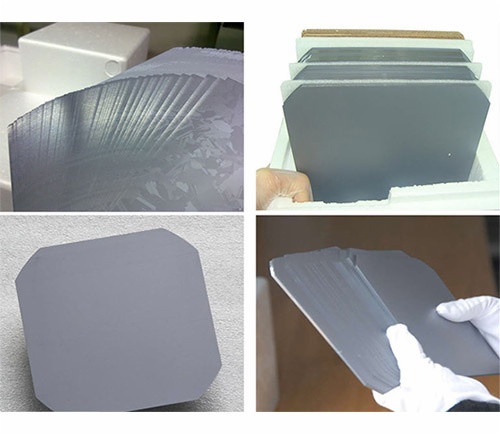

Iimveliso zeJunhe Type-1017 ziyimveliso yecandelo elinye elidityaniswe kakhulu netyuwa ye-potassium, i-corrosion inhibitor, i-complexant, i-detergent kunye ne-surfactant nge-polymerization.I-reagent grade potassium hydroxide inika i-saponification alkalinity.I-polymerization corrosion inhibitor, i-complexant, i-detergent kunye ne-surfactant ibonelela ngokucoca.Le mveliso inomsebenzi omhle kakhulu emulsifying, saponification kunye nokucoca ioli yezilwanyana, ioli yemifuno, i-oyile yamaminerali, ukumiswa kunye nokucola ukucola.Inokuhluba okuqinileyo, ukuntsonkotha kunye nokucoca isiphumo kwiioni zetsimbi.Ukucocwa kwe-oyile yi-99% njengokubona.Ukuhluba, ukuntsonkotha kunye nesiphumo sokucoca ubhedu, intsimbi kunye nezinye iiyoni zetsimbi.Okwangoku, iimveliso ze-Junhe Type-1017 aziqukethe i-phosphate, i-calcium, i-magnesium, isinyithi, ithusi, i-lead kunye nezinye i-ion zensimbi ze-silicon ezinobungozi kwaye zihlangabezana neemfuno ze-EU ROHS ngokukhuselwa kokusingqongileyo kunye nokukwazi ukucoca okunamandla.

2. uphawu

I-1) Iimveliso zeJunhe Type-1017 ziyimveliso ephezulu yogxininiso olulodwa olunokuthi ludityaniswe ngokuqhubekayo kunye nepompo ezenzekelayo kumgca ozenzekelayo.

I-2) Ayiqukethe i-phosphorus kwaye ihlangabezana neemfuno zokusingqongileyo ze-EU ROHS.

3) Kuluhlobo lwemveliso ye-foam ephantsi kwaye ingasetyenziselwa kumgca wokutshiza kunye ne-ultrasonic ngaphandle kwe-foam ephuphumayo.

I-4) Umxholo we-ion yensimbi awudluli i-50PPm ngaphandle kwe-potassium kunye ne-sodium ion kwaye inokuhlangabezana nemfuneko ye-IT yokuchaneka okuphezulu.

I-5) ukusebenza kakuhle kwe-degreasing ukuhlangabezana nemfuno yendawo ye-IT echanekileyo.

3. sebenzisa umyalelo

1) yongeza i-3/4 yamanzi acocekileyo kwi-tank yokucoca kuqala.

2) ukuba uyisebenzisa kumgca wesandla, kucetyiswa ukuba wongeze i-5 ~ 10 kg ye-Junhe Type-1016 ye-silicon yokucoca i-agent yokucoca i-agent kwi-1000 yelitha ye-tank fluid.Xa ucoca ukupolisha kunye nokusila intlama yesilicon chip kunye nesilicon chip cut kunye nokunqunyanyiswa recovery, kufuneka yongeze iidosi ngaphezulu kwiiyure ezisi-8 zokutshintsha ngokuhambelana nenkcazo yenkampani nganye.Ewe kunjalo, nciphisa iidosi xa ugcina isivuno se-silicon chip.

3) Ukuba udibanisa ngokuqhubekayo kumgca ozenzekelayo, vula itanki nge-1 ~ 2 kg Junhe Uhlobo-1017 i-agent ye-silicon yokucoca i-silicon kwi-100 ilitha ye-tank fluid kwaye ulawule ukongezwa okuqhubekayo ngokomgca ozenzekelayo we-silicon yokucoca i-chip.Ngesiphumo esingcono sokucoca, kuyacetyiswa ukuba utshintshe iishifti nganye kwi-1 ~ 3.

4) Ngokubanzi ikhilogram nganye ye-Junhe Type-1017 ye-silicon chip yokucoca i-agent inokucoca ngaphezu kwe-1000 ye-silicon chips ye-125 # i-monocrystal silicon chips.Yongeza ngokwalo mlinganiso.Xa ucoca i-silicone chip kunye ne-silicon chip yokusikwa kunye nokumiswa kokubuyisela, kufuneka yongeze iidosi ezininzi.Ewe kunjalo, nciphisa iidosi xa ugcina isivuno se-silicon chip.

5) Emva koko yongeza amanzi acocekileyo kude kube kwinqanaba lokusebenza kunye nobushushu kwiqondo lokushisa elifunekayo kwaye ungayisebenzisa.

6) I-silicon chip kufuneka ibonakaliswe ngokungaqhelekanga kangangoko kunokwenzeka ngexesha lokucoca ukuze kuthintelwe ukuveliswa kweentyatyambo.

4. amanqaku

I-1) Intonga ye-crystal ayinakumanzi emva kokusika umgca.Ukuba ayinakucocwa ngexesha, kuya kuba ngcono ukuba ifakwe kwi-suspension okanye i-arhente yokucoca (intywiliselwe ngokupheleleyo)

2) Emva kokuba intonga ye-crystal emva kokusikwa komgca ihlanjululwe, kufuneka iqhutywe ngokukhawuleza.Akuvumelekanga ukwenza i-silicon chip yome ngokwemvelo ngexesha lokucoca.

3) Kufuneka ugcine i-silicon chip imanzi xa i-degumming kwaye akufanele iyenze yome ngokwemvelo.

4) Vala i-foaming switch xa i-ultrasonic icoca itanki 1 kunye ne-2. emva kokuba kwiishelufu, vula i-foaming kwaye ugweme ukuveliswa kweqhekeza.

5) emva kokuba umjikelo ngamnye wokucoca ugqityiwe (njengokutshintsha kwenguqu), tshintsha iitanki zamanzi ezicocekileyo zetanki 5, itanki 6, itanki 7 kunye ne-tank 8 ngokucokisekileyo.

I-6) Abasebenzi bokucoca abanako ukuchukumisa i-silicon chip ngexesha lokucoca kwaye kufuneka banxibe iiglavu zerabha kwimeko yokuprintwa kweminwe.

I-7) Ukuze ugcine ukucoceka kwe-silicon chip, ixesha lokucoca ukutshiza ngaphambi kokuba i-degumming ilawulwe ngaphezu kwemizuzu engama-30.

8) Ukuba kukho iingxaki ezifana ne-chip engcolileyo kunye nomlilo ngexesha lokusebenzisa, nceda uqhagamshelane nabasebenzi benkonzo yeteknoloji ngexesha.

9) Xa ukhupha imveliso, idinga i-neutralization, i-flocculation kunye ne-sedimentation kunye nokunye ukucutshungulwa okulula.Imveliso ayinayo isinyithi esinzima kunye ne-orthophosphate.

Idatha yoBugcisa

| Imbonakalo | Ulwelo olungenambala ukuya kumthubi |

| Ubunzima obuthile | 1.00-1.10 |

| PH | 13.0-14.0 |

| Ialkalinity yasimahla (piont) | ≥20mg |