Ubuncinane boMyinge weodolo:Iikhilogram ezili-100

Iinkcukacha zokuPakisha:

Pack A: 16kg / Metal umphanda

Iipakethi B: 24KG iPlasitiki yomphanda

Ipakethe C:Isekwe kwisixa se-arhente A

Ixesha lokuzisa:Kwiintsuku ezilishumi emva kokufumana intlawulo kwangaphambili

Ubunakho bokubonelela:Iitoni ezi-2 ngosuku

Umbala:Isilivere

PH:3.8-5.2

Ubunzima obuthile:1.30±0.05

Viscosity:20~60s(Ukutshiza) 60~90S(Dip-Spin Coating)

Cr6+:≥25g/L

Inkcazo

I-JH-9392 yenziwe ngeepakethe ezintathu: A,B noC;

Ipakethe A: Yisilivere engwevu ludaka oludityaniswe ikakhulu ngokwekhemikhali kunye neflake entle kakhulu iZn, iflake entle kakhulu iAl kunye ne-ethylene glycol.Umlinganiselo weradiyasi-ubunzima be-Zn plate yi-60 ~ 100.

Ipakethi B: Sisinyibilikisi sombala we-orenji-obomvu kunye nesisombululo samanzi, esiqulethe i-Cr6 +.

Ipakethe C: Yeyona nto ibambekayo yokwaleka eyenziwe ikakhulu ngeselulosi emhlophe okanye ngumgubo omthubi.

Ukunciphisa amafutha

I-workpiece kufuneka ihlanjululwe ukuba kukho ioli phezu komhlaba.Kukho iindlela ezintathu zokulungisa:

1.Ubushushu obuphezulu;

2.I-agent engathathi hlangothi yokucoca isiseko samanzi;

3.I-solvent ye-Organic efana ne-methylene chloride.

Ukutyhafa

I-workpiece ayinakugquma ukuba kukho umhlwa okanye i-burr phezu kwe-surface.Eyona ndlela yokucubungula i-shot blasting.Ukuxhatshazwa kwe-corrosion of coating kuya kwenziwa ukuba ukucoca i-asidi yamkelwe.

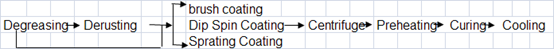

Ukwaleka

I-workpiece afer degreasing kunye nokudutyulwa kokudubula kufuneka kugqunywe ngeDip-Spin coating okanye iSprayiing Coating.

Ukufudumeza kwangaphambili

I-workpiece emva kokuba igqunywe kufuneka ifudunyezwe kwangaphambili ngokukhawuleza kwi-80 ~ 150 ℃ malunga ne-8 ~ 15 mins ukuba ibe ngumphunga.(ngokufunxa ubushushu besixhobo sokusebenza.)

Ukunyanga

I-workpiece emva kokufudumeza kwangaphambili kufuneka iphiliswe kwi-300-340 ℃ kwi-20-40 mins.(ngokufunxa ubushushu besixhobo sokusebenza.)

Ukupakisha

Ipakethe A: 16kg / Metal Barel

Ipakethi B: I-24KG yePlastiki yombhobho

Ipakethe C: i-5.0kg yentsimbi yentsimbi

Ixesha lokuqinisekisa umgangatho

Ngaphambi kokudibanisa iinyanga ezi-6 kwi-20℃

Emva kweentsuku ezingama-40 kwi-20 ℃ (Inokuphinda isetyenziswe ukuba ukongeza i-coating entsha ngokuqhubekayo.)

Kufuneka igcinwe ngaphantsi kwe-20℃ ukuba ayisetyenziswa.

Inkqubo yokwaleka

Mix Ratio

Pack A: 16.0 kg

Ipakethe B:24.0 kg (ubungakanani bunokwandiswa ngokufanelekileyo ukuba kugqunywe isitshizi)

Iipakethi C: 0-50 g (ngokwemfuno ye-viscosity eyahlukeneyo)

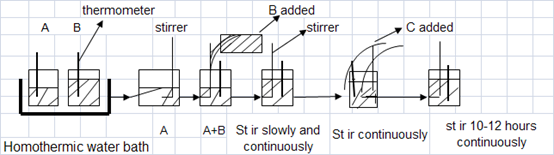

Indlela yokuxuba

Phambi koMxube, Gcina ii-A&B ezinobunzima kwindawo yokuhlambela emanzini kwi-25 ± 2℃, emva koko uvuthulule u-A ukwenza uludaka lwesinyithi lusasazeke ngokufanayo ngomxube wamatyeli, emva kokuba i-A isasazwe ngokulungeleleneyo, nciphisa isantya esiphazamisayo siye kwi-60r/min, kwaye wongeze i-B.

Yongeza u-B ku-A ngokukhawuleza.Okwangoku, iqondo lobushushu lomgqomo liya kunyuka, xa lifikelela kuma-35 ℃, qalisa isixhobo sokukhenkceza ukugcina iqondo lobushushu lomgqomo lingaguquki kuma-35 ℃.

Gxuma umxube malunga neyure ezi-1 ~ 2 ngokukhawuleza emva kokuba u-B egalelwe, uze wongeze u-C. C kufuneka ube ngumgubo ukuba kukho iqhuma. ngokuqhubekayo.

Ukwaleka kufuneka kuhluzwe nge-80 ~ 100 ye-mesh yesikrini sentsimbi engenakutyiwa ngaphambi kokugalelwa kwidiphu yediphu.

Isixhobo sokulawula ubushushu kufuneka sixhotyiswe ngediphu yombhobho ukugcina ubushushu bengubo kuma-22±2℃.

(Ukuba i-temp. iphezulu kakhulu, ipeyinti inoxanduva lokuwohloka, kwaye i-viscosity iya kwenziwa.) I-coating kufuneka ixutywe ngesetyhula ukuze igcinwe ngokulinganayo.

Ukuxinana kovavanyo, i-PH, iqondo lobushushu, i-Viscosity kunye ne-Cr6 + umxholo wokugquma rhoqo kwiiyure ze-8 ukuba isebenza ngokuqhubekayo.

Xuba uMzobo

Ukuqwalaselwa

Ezinye iikhemikhali ezinjengazo naziphi na iintlobo ze-asidi, ityuwa yealkali ayinakuxutywa kwi-coating, kuba ezi zinokuvula i-Zn kunye ne-Al plate ukuze iguge isambatho.

Gwema ukukhanya kwelanga kunye ne-ultraviolet ray ixesha elide xa usebenza, ngaphandle koko kuya kukhawulezisa ukuguga okanye i-polymerization yokwambathisa.

Kubaluleke kakhulu ukulawula ukushisa kwengubo.Ukuba iqondo lobushushu bokwambathisa liyatshintsha xa usebenza, liya kusebenzisa i-viscosity, emva koko i-effec i-quatity yokwambathisa kwi-workpiece.Ke ubudlelwane phakathi kobushushu, i-viscosity kunye nenkqubo yokusonta kufuneka ilawulwe kakuhle xa uqatywa.

I-viscosity iya kuhluka ukuba indlela yokugqoka iyahluka.Khetha idata esezantsi ukuba isitshizi ityabeka, kwaye ukhethe idatha ephezulu ukuba dip spin coating.

Idatha yoBugcisa

| Hayi. | Into | Idatha |

| 1 | PH | 3.8-5.2 |

| 2 | Cr6+ | ≥25g/L |

| 3 | Ubunzima obuthile | 1.30±0.05 |

| 4 | Viscosity | 20 ~ 60s (Spray Coating);60~90S(Dip-Spin Coating) .20℃ Zahn 2 # indebe |

| 5 | Ubushushu bokusebenza | 22±2℃ |