Ukuqulunqwa okuPhambili

| Ukuqamba | Imixholo | Inombolo yeCAS. | Inombolo yeEC. |

| Amanzi acocekileyo | 90-92% | 7732-18-5 | 231-791-2 |

| I-sodium carbonate | 1.0-3.0% | 5968-11-6 | 207-838-8 |

| Ibhloko ye-Acrylic branched compound | 1.0-2.0% | / | / |

| I-surfactant | 1.0-1.5% | 25155-30-0 | 246-680-4 |

| Ukugcina iasidi | 0.1%-1.5% | 137-40-6 | 205-290-4 |

Iimbonakalo

1. Inqanaba eliphezulu lokukhuselwa kwendalo: i-etching ekhethiweyo inokufezekiswa ngaphandle kokusetyenziswa kweziseko eziphilayo ezifana ne-TMAH;

2. Ixabiso eliphantsi lokuvelisa: Xa kuthelekiswa nokuphathwa kwangaphambili okuqhelekileyo kusetyenziswa i-hydrofluoric acid / i-nitric acid kwimarike, ixabiso lemveliso liyancipha kakhulu;

3. Ukusebenza okuphezulu kwe-etching: Xa kuthelekiswa nenkqubo yebhetri yePerc, ukusebenza kakuhle kokuguqulwa kwanda ngaphezu kwe-1.2%;

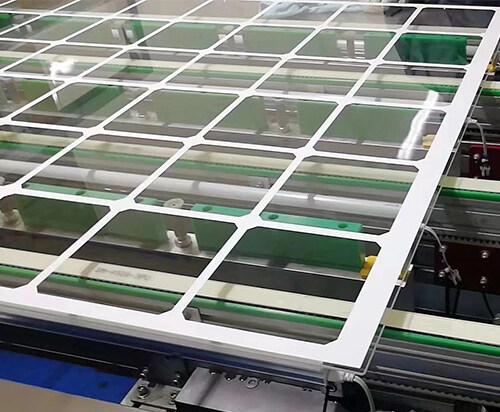

| Ubungakanani bewafer | Imbonakalo | Ukuguqulwa kombane | Ubomi |

| 210 | Umphezulu we-etching uyinto eqhelekileyo kwaye ifilimu enhle ayinayo i-corrosion. | 24.4%~24.6% | 240+ |

IiParameters zobuGcisa

| /L Ukukhutshwa kokuqala kolwelo

| /L Ukufakwa kolwelo | /L Ukuphumla-ukukhupha amanzi | Ubushushu/iqondo | Ixesha lokuphendula/umzuzwana | |

| 48% KOH | 8~10 | 0.3~0,45 | 5~7 | 63-64 | 100-200 |

| I-JH2570 eyongeziweyo | 2.0~4.0 | 0.18~0,21 | |||

| Amanzi acocekileyo | 440.0 | / |

Ezi zakhiwo zinokwahluka ngokuxhomekeke kwikristale enye, inkqubo, ibhetshi kunye nobukhulu.

Usetyenziso

1, Le mveliso ijolise ekususeni i-amorphous silicon yokwambathisa kwiiseli ze-topcon;

I-2, ifanelekile kwiiseli ze-monocrystalline ze-210, i-186, i-166, kunye ne-158 iinkcukacha.

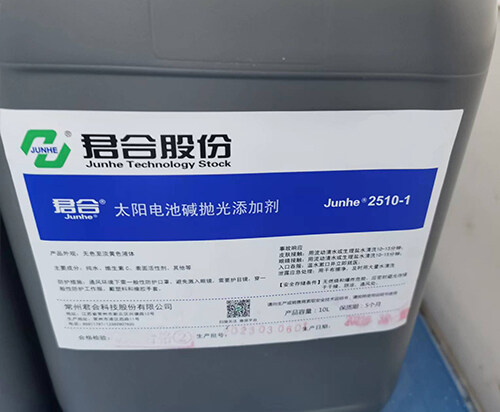

Iimpawu zeMveliso

| Hayi.

| Ipharamitha

| Iiparamitha eziphambili kunye nezalathi zeprojekthi |

| 1 | Umbala, imilo | Ulwelo olungenambala ukuya kolutyheli olucacileyo |

| 2 | PH ixabiso | 7.0-10.0 |

| 3 | ukuxinana | 1.05-1.5g/ml |

| 4 | Iimeko zokugcina | Gcina kwiqondo lobushushu begumbi kude nokukhanya |