IiParameters zobuGcisa

| Ukuqamba | Umxholo | Inombolo yeCAS. |

| Amanzi acocekileyo | 85-90% | 7732-18-5 |

| I-sodium benzoate | 0.1-0.2% | 532-32-1 |

| I-surfactant | 4-5% | ∕ |

| Abanye | 4-5% | ∕ |

Iimpawu zeMveliso

I-1, inqanaba eliphezulu lokukhuselwa kokusingqongileyo: Ukuchongwa okukhethiweyo kunokufezekiswa ngaphandle kokusetyenziswa kweziseko eziphilayo ezifana ne-TMAH.

I-2, Iindleko eziphantsi zemveliso: Ukusebenzisa i-NaOH / KOH njengolwelo lwe-etching, ixabiso liphantsi kakhulu kunenkqubo yokupolisha kunye ne-etching.

3, Ukusebenza okuphezulu kwe-etching: xa kuthelekiswa nenkqubo yokupolisha kunye ne-asidi, ukusebenza kwebhetri konyuka ngaphezu kwe-0.15%.

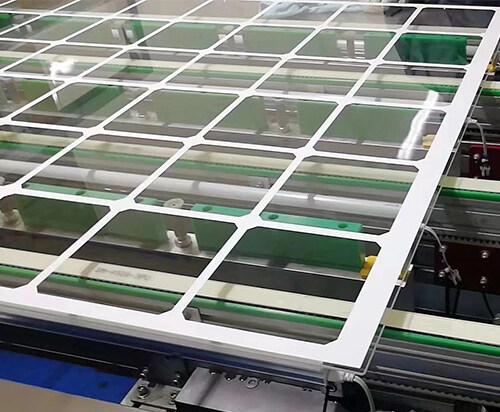

Izicelo zeMveliso

1、 Le mveliso ifanelekile ngokubanzi kwiinkqubo zebhetri zePerc kunye neTopcon;

2, Ilungele iikristale enye ye-210, 186, 166, kunye ne-158 yenkcazo.

Imiyalelo yokusetyenziswa

1, Yongeza isixa esifanelekileyo sealkali kwitanki (1.5-4% ngokusekelwe kumlinganiselo wevolumu ye-KOH/NAOH)

2, Yongeza imali efanelekileyo yale mveliso kwitanki (1.0-2% ngokusekelwe kumlinganiselo wevolumu)

3, Fudumeza ulwelo lwetanki yokukhazimlisa ukuya kuma-60-65°C

4, Beka iwafer yesilicon nge-PSG yangasemva isuswe kwitanki yokupolisha, ixesha lokuphendula yi-180s-250s.

5, Ukunciphisa ubunzima obucetyiswayo kwicala ngalinye: 0.24-0.30g (210 wafer source, eminye imithombo iguqulwa ngomlinganiselo olinganayo) enye kunye ne-polycrystalline PERC iiseli zelanga

Ukulumkela

1, Izongezo kufuneka zigcinwe ngokungqongqo kude nokukhanya.

2, Xa umgca wemveliso ungavelisi, ulwelo kufuneka luzaliswe kwaye lugalelwe yonke imizuzu engama-30.Ukuba akukho mveliso ngaphezu kweeyure ze-2, kuyacetyiswa ukuba ukhuphe kwaye uzalise ulwelo.

3, Ukulungiswa komgca omtsha kufuna uyilo lwe-DOE olusekwe kwinkqubo nganye yomgca wemveliso ukufezekisa ukuhambelana kwenkqubo, ngaloo ndlela ukwandisa ukusebenza kakuhle.Inkqubo ecetyiswayo ingabhekiswa kulungiso lweempazamo.